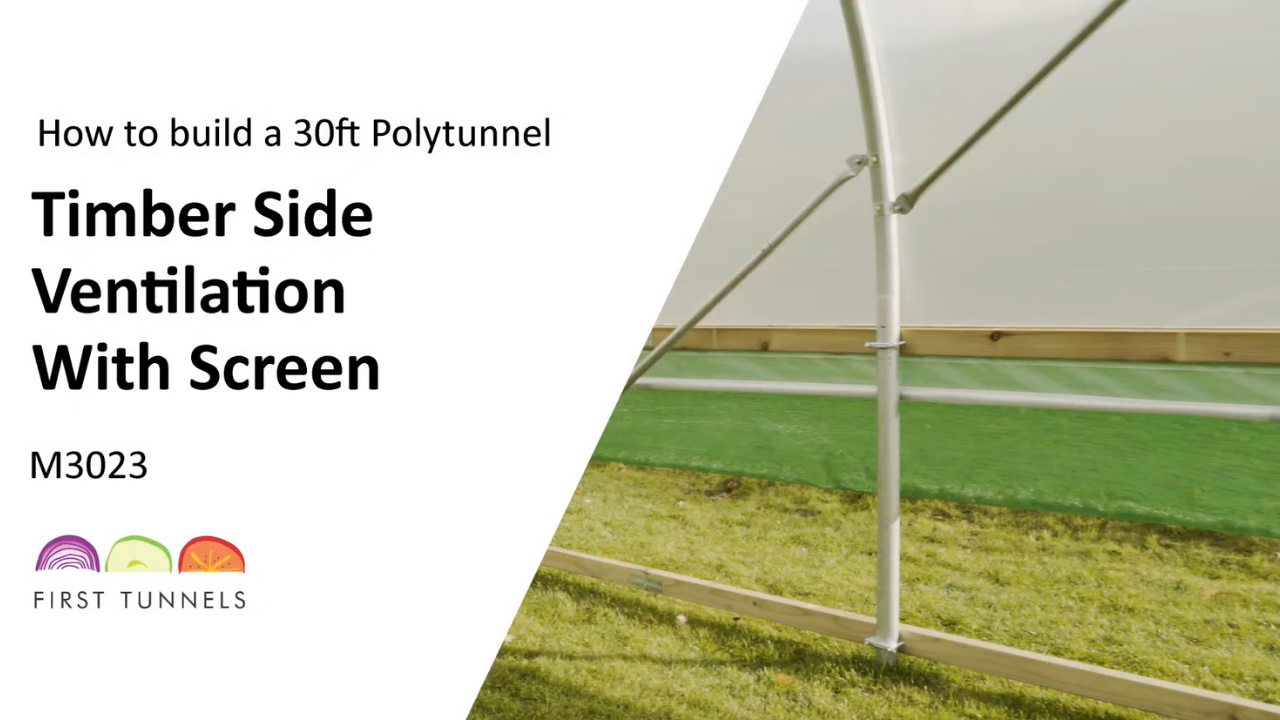

Timber side rails are 47mm x 75mm, commonly known as 3 by 2, and supplied in lengths of 1.8m, 2.4m and 3.2m long (TBR18) (TBR24) (TBR32). The side rail is fitted 75cm above the base rail from the door post to the corner, down the length and returns to the opposite door post (fig 20a). It is fitted using the same method as fitting the base rail with corner (CCT60) and intermediate clamps (ICT60).

Measure from the top of the base rail up the hoop and make a mark at 75cm (fig 20b). This is the position where the bottom of your side rail will sit (fig 20b). Fit a corner clamp to the corner hoop (CCT60). To assemble the corner clamp, place the U bolt around the corner hoop with the threads pointing towards the inside of the polytunnel (fig 20c). Place the tube pressing then corner clamp onto the threads, ensuring the corner clamp wings are parallel to the width and length of your polytunnel. Loosely secure in place.

Locate a 3.2m (TBR32) length of timber and position it down the length of your polytunnel. Ensure the wing of the corner clamp is in the centre of the timber and that the timber is on the outside of the corner clamp wing (fig 20d). Make a mark through the hole of the corner clamp wing. Drill a hole through the mark using a 9mm timber drill bit. Push a bolt through the timber and corner clamp ensuring the thread is on the inside of the polytunnel. Adjust the clamp so that the bottom of the timber is level with the 75cm mark.

To secure the side rail to the intermediate hoop use an intermediate clamp. Ensure your side rail is to the height mark and drill a hole through the timber on each side of the hoop using a 9mm wood drill bit. Place a bolt through each of these holes from the intermediate clamps. An arched pressing is placed over the bolts and secured in place with nuts (fig 20e). To add another section you will need to join another piece of side rail to the one you have just fitted. To join the pieces of side rail you will be required to fit a nail plate to each side of the joint (NP3). Position a nail plate equally across the joint and then secure in place using square twisted nails (fig 20f). Work down the length of your polytunnel joining sections of 3.2m long side rail, finishing with a length 1.8m if required and securing them to the hoops using clamps.

To fit the side rail from the door post to the corner hoop. Use a length of timber 2.4m long (TBR24). Butt an end up to the inside of the corner clamp wing, make a mark through the hole and another mark where you are required to cut the piece in line with the door post. Drill a hole and cut the timber and then reposition the side rail. Secure it to the corner clamp using a washer and nut (fig 20g). Use a spirit level to make sure it is level to the door post. Use a 4mm timber drill bit to drill a pilot hole in the centre of the inside edge of the door post through into the corner rail. Screw a 150mm screw through the hole to secure together. Reinforce the joint from the door post to the side rail with a nail plate and square twisted nail (fig 20h). Nail plates are installed on both sides of the joint. Fit the side rail from the door post to the corner on the opposite end of the polytunnel using the same method. Cut off the excess flush with the end of the polytunnel.

Ventilation netting is fitted from one door post, down the length and returns to the door post on the opposite end of your polytunnel. Roll out the net down the length of your polytunnel. Check that you have enough netting at each end to reach the door post. Start at one end, position the ventilation netting so it is flush with the top of the side rail and staple it in place (fig 20i). If you have ordered timber side ventilation for both sides of your polytunnel, repeat this process on the opposite side.

The next part of the process for installing side ventilation is done once you have fitted your polytunnel cover. This is because during the process of fitting the cover the rails are raised, the cover is attached and then the rails are lowered to add extra tension. Finishing ventilation before the cover has been fitted will hinder the process and will result in the ventilation netting becoming baggy. Please read the section on fitting the polytunnel cover to timber rails and then return to this section to perform the final fit of your ventilation netting.

After your polytunnel cover has been fitted you will be required to secure your side ventilation netting to the base rail and door post. The ventilation netting is secured to the base rail using battens (fig 20j). To speed up the process we recommend pre-nailing a number of battens, nails should be 20cm apart and should not protrude. Starting in the middle and working out to each end pull the side ventilation netting down so it is tight and free of any wrinkles and creases, position a batten flush with the top of the base rail and nail into place. Secure the side ventilation netting to the corner rails using the same method demonstrated earlier. You are also required to install a batten down the door frame post between the base rail and side rail. Pull the netting and secure the batten. Finally, trim off any excess ventilation netting. Repeat this second step on the opposite side of your polytunnel if you have side ventilation on both sides.